Thomas Midgley, Jr.—The Price of Progress

“I’ve had a lot of living in a mighty little while.”

—Thomas Midgley, Jr.

|

In the dozen years Thomas Midgley, Jr. lived in Dayton he revolutionized two industries by inventing tetraethyl “leaded” gasoline and CFC refrigerants. But decades later both inventions proved perilous to billions of people. Midgley was a member of the Engineers Club of Dayton during his most inventive years.

|

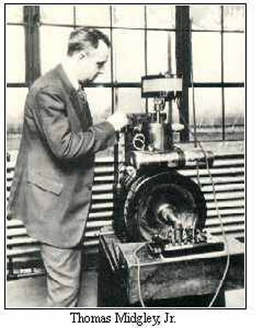

Midgley began tests of countless anti-knock additives in this Delco Light 1-cyclinder engine. He and coworkers set out to test one compound of every chemical element in a scattershot, brute force approach. Over five years the team would slog through as many as 33,000 different additives.

Kettering saw in Midgley the quality of “intelligent ignorance.” Sharp-minded but untrained in chemistry, Midgley was willing to try things the experts “knew” wouldn’t work, and so perhaps solve the impossible. |

How Thomas Midgley, Jr gave cars zoom, homes A/C, saved countless lives, helped win the war and almost doomed us all.

By Mark Martel

“Think global, act local” is an environmentalist catchphrase. But what if the reverse should happen?

In the dozen years Thomas Midgley, Jr. lived in Dayton he revolutionized two industries by inventing tetraethyl “leaded” gasoline and CFC refrigerants worth millions. “Ethyl” brand gas solved the pernicious problem of knock and helped gasoline engine dominate motoring for nearly a century. Chlorofluorocarbons (CFCs) made refrigeration non-toxic and non-flammable, helping air-condition the world and bring life-saving vaccines to millions in the tropics.

For his work he won the top awards in chemistry and was named president of the American Chemical Society. But decades later both inventions proved perilous to billions of people. Midgley’s tragic death is often blamed on his final invention. But there may be more to the story. As Midgley learned chemistry on the job he transitioned from random, brute force methods to predictive, strategic problem solving. His story highlights the peril and promise of “intelligent ignorance”, unintended consequences and the extremes of luck.

Tom Midgley arrived in Dayton, Ohio in 1916 with a young family to support, a cocky attitude, and no job. It was a different world than today with few protections for workers, consumers or the environment. But he knew he was good in his field of mechanical engineering. He’d spent a year at National Cash Register in Dayton before joining his father’s Columbus company to work on better tires for cars. When that business failed the son went on the hunt for a real opportunity, passing over safer choices. It became a pattern.

When the aggressive Midgley showed up in Dayton, inventor Charles Kettering first mistook him for a salesman. But he soon hired Midgley for one of the new companies he had spun off of the success of Delco. Kettering had struck it rich five years prior by inventing the electric starter for cars, but now some were blaming his Delco starters for engine knock.

If you imagine the wheezing, chugging, racket of an old-timey automobile—that was knock, and it was serious. Knock robbed cars of gas mileage, power and could even destroy an engine. It was a major roadblock to the gasoline engine overtaking cars powered by steam or electricity. Kettering wanted to solve the knock problem for the entire industry. Geologists had been predicting an oil shortage. The future might depend on some hybrid fuel that extended gasoline with additives like alcohol. Kettering saw in Midgley the quality of “intelligent ignorance.” Sharp-minded but untrained in chemistry, Midgley was willing to try things the experts “knew” wouldn’t work, and so perhaps solve the impossible.

Immediately the two got incredibly lucky. They jury-rigged a contraption to photograph inside an engine as it ran, and the results confirmed Kett’s suspicion. The fuel wasn’t burning completely. Thus knock wasn’t the fault of his electric ignition, but the fault of the fuel itself. So what then? Outside in the cold, one of them noticed a trailing arbutus poking up through the snow. The red leaves absorbed enough of the sun’s heat to melt the surrounding snow. Maybe something red would help gasoline burn hotter? The only red substance in the supply cabinet was iodine, and against astounding odds it worked. Iodine reduced the knock substantially, though at the cost of heavy engine damage. Iodine was out of the question. But it had proved a cure for engine knock was possible.

Kettering started with a wide search. The fix for knock might require adding a small splash of something to gasoline, or a larger amount, like today’s 10% ethanol. As WWI began, Midgley was reassigned to improve aviation fuel for the Liberty Engine that would power American airplanes (see Colonel Deeds article). Midgley explored the large percentage route through mixtures of gasoline, kerosene, ethyl alcohol and other substances. He finally settled on 20% benzol and 80% cyclohexane, enabling higher engine compression—power.

After the war Midgley returned to the engine knock problem and his team followed both trails, using a trial and error method of testing whatever was on hand in a 1-cylinder Delco Light engine, an electric generator for farms. Due to fire rules it had to run on kerosene, and as a result it knocked violently, reducing compression and efficiency. So the tabletop device made an ideal test bed. They set out to try a compound of every element out there.

As a youth this brute force approach had helped Midgley perfect the spitball for baseball pitchers. He and a buddy tried all sorts of common substances until they found that slippery elm bark made pitches curve the most. The idea spread all through baseball. Solving knock started similarly, but countless chemical compounds were known to man. Over five years the team would slog through as many as 33,000 different additives.

But there were side benefits to the job. Working for Kettering meant joining his new Engineers Club of Dayton. Midgley is listed as a member for the 1918 opening of the Club building, and he probably remained a member even after moving to Columbus. Men from Delco and related Kettering enterprises would walk the few blocks for lunch at the club and share ideas around Boss Kett’s roundtable. Created so that technical men (the first woman joined a decade later) could “hunt together,” the club must have been the perfect environment for an aggressive extrovert like Midgley. He was known to spout a bit of his own poetry, and would prove an adept showman of his own inventions.

Midgley’s creativity showed one day when he dreamed up the idea of packaging an ice cube with frozen peas, to prove they had not melted during shipping. The idea became just one of his 100 patents. Henry Ford had championed a gas-alcohol mixture to prevent knock. But with the new national Prohibition on booze, marketing a product that required vast amounts of alcohol might be a disaster. And even if that proved practical, anyone could enter the market and rob sales.

These concerns didn’t seem to stop Midgley and coworkers from imbibing. Speakeasy saloons dotted the downtown. A Midgley Valentine’s Day telegram to his wife read, “I’ve got whiskey, I’ve got wine, won’t you be my valentine?” At conventions he and Kettering were known to stir up some of the new screwdrivers. Midgley said, "I have always had a fondness for intelligent people. And the more we drink, the smarter we get." He reportedly made excellent gin.

The lab had trouble getting hold of alcohol for experiments. Yet before Prohibition would end in 1933, assistant Carroll Hochwalt was sitting on a patent for a quicker method to brew whiskey. Midgley seemed convinced of his own indestructibility. Patent attorney Laurence Langner claimed Midgley “used to drink the Ethyl gas just to show his contempt for humanity,” and had a habit of testing out all kinds of chemicals on his own system. ”That man is full of floating benzene rings. I wonder how he manages to stay alive!” Langner had a love for the dramatic.

So did Midgley. In 1921 he drove to Indianapolis on a gasoline-ethanol mixture to dramatize how it raised engine compression. He was known to recite Casey at the Bat and his own poems, but the highest drama was to come.

On the last day of 1918 GM acquired Kettering’s various companies. Boss Kett turned up the heat on the anti-knock team, now working in an old converted residence on Ludlow Street: “By God, if you don’t come up with something within the next three to six months you’re all fired.” Four long weeks later assistant Thomas Boyd stumbled upon aniline, which cut knock effectively. But it stunk so bad Midgley’s wife made him sleep in the basement. “I doubt if humanity, even to doubling their fuel economy, will put up with this smell,” he said. The lab spent months trying to make aniline bearable, then finally moved on. Boyd was sent off to investigate gas-alcohol options.

By the spring of 1921 with no breakthroughs, Midgley begged for a new assignment. Kettering was leaving on a business trip, and postponed his answer until his return. By chance he’d found a newspaper clipping about the element selenium. Sure enough, it reduced knock substantially. But the compound produced a terrible garlicky smell. Within days tellurium proved even more effective but just as smelly. The men toiled on.

By now they had tested as many as 33,000 compounds, by one estimate. Along the way, lab manager F.C. Clements noted that most coworkers had “given him very little encouragement." But the growing clues began to hint at a solution. School chum Robert E. Wilson had just come up with a new version of the Periodic Table of Elements, arranged by how many electrons each atom had. In this arrangement the elements iodine, tellurium and selenium formed a clump that pointed toward lead. The hunt turned more scientific as Midgley and team tested compounds in the series. Then on December 9, 1921 assistant Carroll Hochwalt mixed up lead in an alcohol solution, tetra-ethyl lead (TEL). “Hell, it was eureka.”

A 1 part per 100 mix of tetra-ethyl lead in gasoline silenced engine knock. They cut the amount of TEL by half and it still worked. And then half that worked. In the end .025% of TEL in kerosene proved enough to solve engine knock, and Boss Kett began to smell success despite lingering problems. The leaded gasoline left engine deposits. But Kett ruled it was time to take the product to market and let customer feedback define the most crucial problems to fix. Otherwise they’d lose their shirt trying to perfect every aspect.

Kettering was a showman too. He took the tetra-ethyl lead additive and renamed it Ethyl. Ethyl was cute—a woman’s name that also implied ethyl alcohol, a long-tried additive to gasoline. And the name didn’t suggest lead at all. A Dayton oil refinery started making batches of Ethyl and put it on sale February 1st, 1923. Soon customers learned their extra couple of cents per gallon were worth it. Cars stopped knocking themselves to pieces and gave much better horsepower. Word of mouth spread.

The use of lead also rang alarms in academia. In the days before the EPA and OSHA protected consumers and workers, safety was valued far less. Lead’s dangers had been known for centuries in industries like pottery. But Midgley’s lack of expertise in chemistry—the “intelligent ignorance” that Kettering valued—meant ignorance of hard-won lessons in safety too. The consequences would be fatal.

Lead poisoning occurs quietly. Signs don’t appear until high levels have built up in the body. In early 1923, after Midgley developed symptoms like tuberculosis and complained of “lead-lined lungs”, he took a six-week rest in Florida. Hochwalt went on a long honeymoon, also ill. At the Dayton oil refinery producing the Ethyl fluid, greater ignorance and complacency prevailed—until 60 of the men were sickened and two died. Kettering blamed the men for not recognizing the danger. "We could not get this across to the boys."The cause of the deaths was kept secret, and to this day the victims’ identities are unknown—and are now shrouded by privacy laws. Midgley was despondent and considered quitting. But Kettering counseled this was the unavoidable price of progress.

Earlier in Florida, he had come to an astounding realization. Lead was cheap to mine. Ethyl was cheap to make. And a few drops of the additive justified a premium price for gas. The math showed a profit potential so enormous that within months General Motors and Standard Oil swiftly created the Ethyl Corporation, naming Kettering its president and Midgley vice president. Ethyl swiftly expanded nationwide. While in Florida Midgley had written an oil industry executive, noting that tetra-ethyl lead stings and burns on contact with the skin, so that the poisoning of those handling the pure fluid would be “almost impossible.”

Then, as production shifted to east coast refineries, there came more fatalities. Five men died at a Standard Oil refinery, plus eight more at Du Pont, and this time their deaths were linked publicly to the Ethyl additive. Public outcry arose, and with it a knowledge gap. At a hasty press conference the ever-dramatic Midgley sought to prove consumer safety by washing his hands in what seemed to be the Ethyl fluid. ''I'm not taking any chance whatever... Nor would I take any chance doing that every day."

But was this the vastly diluted Ethyl-treated gasoline, or the pure, deadly additive? Meant to appear a Mr. Wizard, Midgley must have seemed more a Pontius Pilate to some. The worker deaths were put down to temporary development issues, and consumer safety was stressed, as the Ethyl gas contained such a vastly diluted amount of its mystery additive.

Kettering and Midgley lost their Ethyl positions, as the Surgeon General called a conference in 1925. Academic experts testified to the dangers, but industry representatives eventually outmaneuvered them. Ethyl went back on the market a year later—five million dollars in the red, but with tightened refinery procedures and a strong marketing campaign. No more refinery deaths were reported. And soon consumers were buying gas from Ethyl and competitors like Gulf No-Nox for the added pep. New discoveries in the Middle East had put to rest fears of oil shortages for now.

Tetraethyl lead quickly became a standard component of gasoline in the United States. Britain’s petroleum secretary during WWII claimed the fuel helped win the aerial Battle of Britain against German planes. And during the decades it was on the market, its use saved a large percentage of the gasoline that might have been burned. But all that lead went somewhere. Industry had promised to study the long term effects, but it would take the work of a researcher in a totally unconnected field to find the answer. While determining the age of the earth through radioactive decay of Plutonium, geochemist Clair Patterson discovered that atmospheric lead had shot up around 1923—right when Ethyl went on the market.

Patterson’s development of ultra-pure lab techniques and polar ice core work, combined with lead studies on children proved the connection by the early 1960s. After Ethyl was taken off market in the 1970s, blood levels dropped and child IQs rose. Lead toxicity remains an issue in poor areas, especially in places where lead exhaust accumulated over the decades and in the less regulated third world.

In 1928, Midgley’s final year living in Dayton, Kettering approached him with a new problem. The leading refrigeration company, Frigidaire, was part of GM, and boss Kett had decided they needed a new refrigerant. The existing chemicals were remarkably toxic and flammable, with many highly publicized deaths. Within months 100 would die in a Cleveland hospital.

Solving engine knock had taken five years; this problem took three days. Midgley knew the properties of an ideal refrigerant—nonflammable, non-toxic, stable and with a boiling point between 0 and -40C. At lunch he and two assistants studied a pocket-sized periodic table. Fluorine was perfect, except it was toxic. But what about one of its compounds?

"Plots of boiling points, hunts for data, corrections, slide rules, log paper, eraser dirt, pencil shavings, and all the rest of the paraphernalia that takes the place of tea leaves and crystal spheres in the life of the scientific clairvoyant, were brought into play," Midgley is quoted in the excellent Prometheans in the Lab. But soon “everything seemed right” as they realized they had uncovered a whole class of compounds that would be known as chlorofluorocarbons or CFCs. After Albert Henne prepared dichlorodifluoromethane, or R12, it performed perfectly. Too perfectly as it would turn out.

Next year the Midgleys moved to his hometown of Columbus where he built an estate and pursued his own research into synthetic rubber. He had turned down a GM vice presidency but remained a consultant, vice president at Ethyl and board member at Ethyl-Dow.

In 1930 he unveiled his refrigerant, dubbed “Freon,” with typical drama at the American Chemical Society. He lit a candle, boiled some Freon in a bowl then inhaled the vapor and blew out the candle. He had proved his new creation was nontoxic and inflammable at one stroke. And again put his health on the line to do so. Safe refrigeration was a boon to mankind. People could bring in the icebox from the porch without worrying it might be lethal. Air conditioning, reduced food poisoning and refrigerated vaccines enabled better life worldwide for millions.

From 1922-1942 Midgley’s accomplishments were rewarded with chemistry’s four highest medals, the Nichols, Perkin, Priestley and Willard Gibbs Medals. He was elected president of the American Chemical Society, and enjoyed the comforts of wealth—a 50 acre estate, full wine cellar, golf and the freedom to pursue pure science. All that came to an abrupt end in 1940 when within hours paralysis struck him from the waist down. The diagnosis was polio. He figured the odds for someone his age to contract the disease as "substantially equal to the chances of drawing a certain individual card from a stack of playing cards as high as the Empire State Building."

One can’t help wondering if his long-term exposure to lead along with the rest of the periodic table might not have contributed to his severe symptoms. Ironically, Midgley received therapy at the Columbus Children’s Hospital, where young victims of lead poisoning were also treated. Despite some improvement he remained paralyzed from the waist down, and began clearing up his affairs. In his final presidential address he urged older chemists to step aside for younger minds, who historically have made the greatest advancements before age 45.

Midgley designed a system of pulleys to help him out of bed and he seemed to keep going. In 1944 he was elected president and chairman of the American Chemical Society. But one morning in November his wife Carrie found him strangled in the device, dead at age 55. Today his detractors see this as cosmic irony, but for such a gifted engineer, accidental death seems questionable.

Though Thomas Midgley, Jr.’s work transformed two industries, earned millions, and perhaps helped win World War II, it later earned him such vilification that environmental historian J. R. McNeill dubbed him “the single most dangerous organism in the history of the Earth.” Or was his old boss Kettering right that “the price of progress is trouble?” Putting a non-chemist in charge of the anti-knock problem enabled creative, out-of-the-box thinking. But it came at the cost of underestimating an insidious neural toxin. Huge profits and the human propensity for short-term thinking swept aside promises to study lead’s gradual risks.

But that’s hindsight. It was forty years after Ethyl’s introduction before geochemist Clair Patterson developed the ultraclean lab techniques to spot the buildup of atmospheric lead and go public with his findings. By the early 1970s the EPA introduced a ban on TEL (tetraethyl lead), and child lead levels began dropping by the 1980s. Today most of the world has banned TEL except in aviation. As our ability to detect lower levels of lead has grown, scientists have discovered the effects of lead toxicity at ever-smaller amounts. Ground residue from decades of lead exhaust remains an issue in older urban areas.

By the time lead came off the market, Midgley’s second great invention, chlorofluorocarbons, were found to be a threat to the atmosphere as well. CFC compounds were so stable they remained in the upper atmosphere for long periods of time. In 1974, scientists Molina and Rowland identified CFCs as damaging to the ozone layer, for which they later won the Nobel Prize. By 1978 the US moved to ban the chemicals from the market, and the rest of world followed suit. Today holes in the ozone layer are healing, but CFCs can take decades to decay, prolonging the damage. Meanwhile political threats to the embargo continue.

Midgley himself came to the rescue. A second class of safer “HFC” hydrofluorocarbons he discovered became replacement refrigerants. But one solution generates new problems—HFCs have now been identified as short-lived but powerful greenhouse gases. In either case, Midgley should be blameless. No one in 1928 could have foreseen the effects of such a discovery.

And that may be the true, unavoidable price of progress as Kettering saw it. Sometimes we have the expertise to predict the effects of our actions. But often there is no way of knowing. Social attitudes towards risk have also evolved since Midgley’s day. Advances in medicine and geoscience enable “better living through chemistry.” But the environmental and worker protections of a few decades back have been met with new pendulum swings favoring industry and globalization. As science accelerates the discovery of new compounds, we live with an ongoing struggle to balance the needs of industry, government and the public.

So today we face the same quandaries that Midgley did. Do we wash our hands of responsibility for the effects of new products and substance, or do we step back and wait for the judgment of experts? Is that even an option when the fastest to market wins?

Internet discussions about Midgley reliably spark extreme attitudes and snap judgments, from full condemnation to total support. The website climateandsecurity.org contends that Midgley has started us on the road to geo-engineering our planet’s future. Perhaps the best legacy of Thomas Midgley, Jr. is the power his story has to make us re-examine the price—and promise—of progress.

“Think global, act local” is an environmentalist catchphrase. But what if the reverse should happen?

In the dozen years Thomas Midgley, Jr. lived in Dayton he revolutionized two industries by inventing tetraethyl “leaded” gasoline and CFC refrigerants worth millions. “Ethyl” brand gas solved the pernicious problem of knock and helped gasoline engine dominate motoring for nearly a century. Chlorofluorocarbons (CFCs) made refrigeration non-toxic and non-flammable, helping air-condition the world and bring life-saving vaccines to millions in the tropics.

For his work he won the top awards in chemistry and was named president of the American Chemical Society. But decades later both inventions proved perilous to billions of people. Midgley’s tragic death is often blamed on his final invention. But there may be more to the story. As Midgley learned chemistry on the job he transitioned from random, brute force methods to predictive, strategic problem solving. His story highlights the peril and promise of “intelligent ignorance”, unintended consequences and the extremes of luck.

Tom Midgley arrived in Dayton, Ohio in 1916 with a young family to support, a cocky attitude, and no job. It was a different world than today with few protections for workers, consumers or the environment. But he knew he was good in his field of mechanical engineering. He’d spent a year at National Cash Register in Dayton before joining his father’s Columbus company to work on better tires for cars. When that business failed the son went on the hunt for a real opportunity, passing over safer choices. It became a pattern.

When the aggressive Midgley showed up in Dayton, inventor Charles Kettering first mistook him for a salesman. But he soon hired Midgley for one of the new companies he had spun off of the success of Delco. Kettering had struck it rich five years prior by inventing the electric starter for cars, but now some were blaming his Delco starters for engine knock.

If you imagine the wheezing, chugging, racket of an old-timey automobile—that was knock, and it was serious. Knock robbed cars of gas mileage, power and could even destroy an engine. It was a major roadblock to the gasoline engine overtaking cars powered by steam or electricity. Kettering wanted to solve the knock problem for the entire industry. Geologists had been predicting an oil shortage. The future might depend on some hybrid fuel that extended gasoline with additives like alcohol. Kettering saw in Midgley the quality of “intelligent ignorance.” Sharp-minded but untrained in chemistry, Midgley was willing to try things the experts “knew” wouldn’t work, and so perhaps solve the impossible.

Immediately the two got incredibly lucky. They jury-rigged a contraption to photograph inside an engine as it ran, and the results confirmed Kett’s suspicion. The fuel wasn’t burning completely. Thus knock wasn’t the fault of his electric ignition, but the fault of the fuel itself. So what then? Outside in the cold, one of them noticed a trailing arbutus poking up through the snow. The red leaves absorbed enough of the sun’s heat to melt the surrounding snow. Maybe something red would help gasoline burn hotter? The only red substance in the supply cabinet was iodine, and against astounding odds it worked. Iodine reduced the knock substantially, though at the cost of heavy engine damage. Iodine was out of the question. But it had proved a cure for engine knock was possible.

Kettering started with a wide search. The fix for knock might require adding a small splash of something to gasoline, or a larger amount, like today’s 10% ethanol. As WWI began, Midgley was reassigned to improve aviation fuel for the Liberty Engine that would power American airplanes (see Colonel Deeds article). Midgley explored the large percentage route through mixtures of gasoline, kerosene, ethyl alcohol and other substances. He finally settled on 20% benzol and 80% cyclohexane, enabling higher engine compression—power.

After the war Midgley returned to the engine knock problem and his team followed both trails, using a trial and error method of testing whatever was on hand in a 1-cylinder Delco Light engine, an electric generator for farms. Due to fire rules it had to run on kerosene, and as a result it knocked violently, reducing compression and efficiency. So the tabletop device made an ideal test bed. They set out to try a compound of every element out there.

As a youth this brute force approach had helped Midgley perfect the spitball for baseball pitchers. He and a buddy tried all sorts of common substances until they found that slippery elm bark made pitches curve the most. The idea spread all through baseball. Solving knock started similarly, but countless chemical compounds were known to man. Over five years the team would slog through as many as 33,000 different additives.

But there were side benefits to the job. Working for Kettering meant joining his new Engineers Club of Dayton. Midgley is listed as a member for the 1918 opening of the Club building, and he probably remained a member even after moving to Columbus. Men from Delco and related Kettering enterprises would walk the few blocks for lunch at the club and share ideas around Boss Kett’s roundtable. Created so that technical men (the first woman joined a decade later) could “hunt together,” the club must have been the perfect environment for an aggressive extrovert like Midgley. He was known to spout a bit of his own poetry, and would prove an adept showman of his own inventions.

Midgley’s creativity showed one day when he dreamed up the idea of packaging an ice cube with frozen peas, to prove they had not melted during shipping. The idea became just one of his 100 patents. Henry Ford had championed a gas-alcohol mixture to prevent knock. But with the new national Prohibition on booze, marketing a product that required vast amounts of alcohol might be a disaster. And even if that proved practical, anyone could enter the market and rob sales.

These concerns didn’t seem to stop Midgley and coworkers from imbibing. Speakeasy saloons dotted the downtown. A Midgley Valentine’s Day telegram to his wife read, “I’ve got whiskey, I’ve got wine, won’t you be my valentine?” At conventions he and Kettering were known to stir up some of the new screwdrivers. Midgley said, "I have always had a fondness for intelligent people. And the more we drink, the smarter we get." He reportedly made excellent gin.

The lab had trouble getting hold of alcohol for experiments. Yet before Prohibition would end in 1933, assistant Carroll Hochwalt was sitting on a patent for a quicker method to brew whiskey. Midgley seemed convinced of his own indestructibility. Patent attorney Laurence Langner claimed Midgley “used to drink the Ethyl gas just to show his contempt for humanity,” and had a habit of testing out all kinds of chemicals on his own system. ”That man is full of floating benzene rings. I wonder how he manages to stay alive!” Langner had a love for the dramatic.

So did Midgley. In 1921 he drove to Indianapolis on a gasoline-ethanol mixture to dramatize how it raised engine compression. He was known to recite Casey at the Bat and his own poems, but the highest drama was to come.

On the last day of 1918 GM acquired Kettering’s various companies. Boss Kett turned up the heat on the anti-knock team, now working in an old converted residence on Ludlow Street: “By God, if you don’t come up with something within the next three to six months you’re all fired.” Four long weeks later assistant Thomas Boyd stumbled upon aniline, which cut knock effectively. But it stunk so bad Midgley’s wife made him sleep in the basement. “I doubt if humanity, even to doubling their fuel economy, will put up with this smell,” he said. The lab spent months trying to make aniline bearable, then finally moved on. Boyd was sent off to investigate gas-alcohol options.

By the spring of 1921 with no breakthroughs, Midgley begged for a new assignment. Kettering was leaving on a business trip, and postponed his answer until his return. By chance he’d found a newspaper clipping about the element selenium. Sure enough, it reduced knock substantially. But the compound produced a terrible garlicky smell. Within days tellurium proved even more effective but just as smelly. The men toiled on.

By now they had tested as many as 33,000 compounds, by one estimate. Along the way, lab manager F.C. Clements noted that most coworkers had “given him very little encouragement." But the growing clues began to hint at a solution. School chum Robert E. Wilson had just come up with a new version of the Periodic Table of Elements, arranged by how many electrons each atom had. In this arrangement the elements iodine, tellurium and selenium formed a clump that pointed toward lead. The hunt turned more scientific as Midgley and team tested compounds in the series. Then on December 9, 1921 assistant Carroll Hochwalt mixed up lead in an alcohol solution, tetra-ethyl lead (TEL). “Hell, it was eureka.”

A 1 part per 100 mix of tetra-ethyl lead in gasoline silenced engine knock. They cut the amount of TEL by half and it still worked. And then half that worked. In the end .025% of TEL in kerosene proved enough to solve engine knock, and Boss Kett began to smell success despite lingering problems. The leaded gasoline left engine deposits. But Kett ruled it was time to take the product to market and let customer feedback define the most crucial problems to fix. Otherwise they’d lose their shirt trying to perfect every aspect.

Kettering was a showman too. He took the tetra-ethyl lead additive and renamed it Ethyl. Ethyl was cute—a woman’s name that also implied ethyl alcohol, a long-tried additive to gasoline. And the name didn’t suggest lead at all. A Dayton oil refinery started making batches of Ethyl and put it on sale February 1st, 1923. Soon customers learned their extra couple of cents per gallon were worth it. Cars stopped knocking themselves to pieces and gave much better horsepower. Word of mouth spread.

The use of lead also rang alarms in academia. In the days before the EPA and OSHA protected consumers and workers, safety was valued far less. Lead’s dangers had been known for centuries in industries like pottery. But Midgley’s lack of expertise in chemistry—the “intelligent ignorance” that Kettering valued—meant ignorance of hard-won lessons in safety too. The consequences would be fatal.

Lead poisoning occurs quietly. Signs don’t appear until high levels have built up in the body. In early 1923, after Midgley developed symptoms like tuberculosis and complained of “lead-lined lungs”, he took a six-week rest in Florida. Hochwalt went on a long honeymoon, also ill. At the Dayton oil refinery producing the Ethyl fluid, greater ignorance and complacency prevailed—until 60 of the men were sickened and two died. Kettering blamed the men for not recognizing the danger. "We could not get this across to the boys."The cause of the deaths was kept secret, and to this day the victims’ identities are unknown—and are now shrouded by privacy laws. Midgley was despondent and considered quitting. But Kettering counseled this was the unavoidable price of progress.

Earlier in Florida, he had come to an astounding realization. Lead was cheap to mine. Ethyl was cheap to make. And a few drops of the additive justified a premium price for gas. The math showed a profit potential so enormous that within months General Motors and Standard Oil swiftly created the Ethyl Corporation, naming Kettering its president and Midgley vice president. Ethyl swiftly expanded nationwide. While in Florida Midgley had written an oil industry executive, noting that tetra-ethyl lead stings and burns on contact with the skin, so that the poisoning of those handling the pure fluid would be “almost impossible.”

Then, as production shifted to east coast refineries, there came more fatalities. Five men died at a Standard Oil refinery, plus eight more at Du Pont, and this time their deaths were linked publicly to the Ethyl additive. Public outcry arose, and with it a knowledge gap. At a hasty press conference the ever-dramatic Midgley sought to prove consumer safety by washing his hands in what seemed to be the Ethyl fluid. ''I'm not taking any chance whatever... Nor would I take any chance doing that every day."

But was this the vastly diluted Ethyl-treated gasoline, or the pure, deadly additive? Meant to appear a Mr. Wizard, Midgley must have seemed more a Pontius Pilate to some. The worker deaths were put down to temporary development issues, and consumer safety was stressed, as the Ethyl gas contained such a vastly diluted amount of its mystery additive.

Kettering and Midgley lost their Ethyl positions, as the Surgeon General called a conference in 1925. Academic experts testified to the dangers, but industry representatives eventually outmaneuvered them. Ethyl went back on the market a year later—five million dollars in the red, but with tightened refinery procedures and a strong marketing campaign. No more refinery deaths were reported. And soon consumers were buying gas from Ethyl and competitors like Gulf No-Nox for the added pep. New discoveries in the Middle East had put to rest fears of oil shortages for now.

Tetraethyl lead quickly became a standard component of gasoline in the United States. Britain’s petroleum secretary during WWII claimed the fuel helped win the aerial Battle of Britain against German planes. And during the decades it was on the market, its use saved a large percentage of the gasoline that might have been burned. But all that lead went somewhere. Industry had promised to study the long term effects, but it would take the work of a researcher in a totally unconnected field to find the answer. While determining the age of the earth through radioactive decay of Plutonium, geochemist Clair Patterson discovered that atmospheric lead had shot up around 1923—right when Ethyl went on the market.

Patterson’s development of ultra-pure lab techniques and polar ice core work, combined with lead studies on children proved the connection by the early 1960s. After Ethyl was taken off market in the 1970s, blood levels dropped and child IQs rose. Lead toxicity remains an issue in poor areas, especially in places where lead exhaust accumulated over the decades and in the less regulated third world.

In 1928, Midgley’s final year living in Dayton, Kettering approached him with a new problem. The leading refrigeration company, Frigidaire, was part of GM, and boss Kett had decided they needed a new refrigerant. The existing chemicals were remarkably toxic and flammable, with many highly publicized deaths. Within months 100 would die in a Cleveland hospital.

Solving engine knock had taken five years; this problem took three days. Midgley knew the properties of an ideal refrigerant—nonflammable, non-toxic, stable and with a boiling point between 0 and -40C. At lunch he and two assistants studied a pocket-sized periodic table. Fluorine was perfect, except it was toxic. But what about one of its compounds?

"Plots of boiling points, hunts for data, corrections, slide rules, log paper, eraser dirt, pencil shavings, and all the rest of the paraphernalia that takes the place of tea leaves and crystal spheres in the life of the scientific clairvoyant, were brought into play," Midgley is quoted in the excellent Prometheans in the Lab. But soon “everything seemed right” as they realized they had uncovered a whole class of compounds that would be known as chlorofluorocarbons or CFCs. After Albert Henne prepared dichlorodifluoromethane, or R12, it performed perfectly. Too perfectly as it would turn out.

Next year the Midgleys moved to his hometown of Columbus where he built an estate and pursued his own research into synthetic rubber. He had turned down a GM vice presidency but remained a consultant, vice president at Ethyl and board member at Ethyl-Dow.

In 1930 he unveiled his refrigerant, dubbed “Freon,” with typical drama at the American Chemical Society. He lit a candle, boiled some Freon in a bowl then inhaled the vapor and blew out the candle. He had proved his new creation was nontoxic and inflammable at one stroke. And again put his health on the line to do so. Safe refrigeration was a boon to mankind. People could bring in the icebox from the porch without worrying it might be lethal. Air conditioning, reduced food poisoning and refrigerated vaccines enabled better life worldwide for millions.

From 1922-1942 Midgley’s accomplishments were rewarded with chemistry’s four highest medals, the Nichols, Perkin, Priestley and Willard Gibbs Medals. He was elected president of the American Chemical Society, and enjoyed the comforts of wealth—a 50 acre estate, full wine cellar, golf and the freedom to pursue pure science. All that came to an abrupt end in 1940 when within hours paralysis struck him from the waist down. The diagnosis was polio. He figured the odds for someone his age to contract the disease as "substantially equal to the chances of drawing a certain individual card from a stack of playing cards as high as the Empire State Building."

One can’t help wondering if his long-term exposure to lead along with the rest of the periodic table might not have contributed to his severe symptoms. Ironically, Midgley received therapy at the Columbus Children’s Hospital, where young victims of lead poisoning were also treated. Despite some improvement he remained paralyzed from the waist down, and began clearing up his affairs. In his final presidential address he urged older chemists to step aside for younger minds, who historically have made the greatest advancements before age 45.

Midgley designed a system of pulleys to help him out of bed and he seemed to keep going. In 1944 he was elected president and chairman of the American Chemical Society. But one morning in November his wife Carrie found him strangled in the device, dead at age 55. Today his detractors see this as cosmic irony, but for such a gifted engineer, accidental death seems questionable.

Though Thomas Midgley, Jr.’s work transformed two industries, earned millions, and perhaps helped win World War II, it later earned him such vilification that environmental historian J. R. McNeill dubbed him “the single most dangerous organism in the history of the Earth.” Or was his old boss Kettering right that “the price of progress is trouble?” Putting a non-chemist in charge of the anti-knock problem enabled creative, out-of-the-box thinking. But it came at the cost of underestimating an insidious neural toxin. Huge profits and the human propensity for short-term thinking swept aside promises to study lead’s gradual risks.

But that’s hindsight. It was forty years after Ethyl’s introduction before geochemist Clair Patterson developed the ultraclean lab techniques to spot the buildup of atmospheric lead and go public with his findings. By the early 1970s the EPA introduced a ban on TEL (tetraethyl lead), and child lead levels began dropping by the 1980s. Today most of the world has banned TEL except in aviation. As our ability to detect lower levels of lead has grown, scientists have discovered the effects of lead toxicity at ever-smaller amounts. Ground residue from decades of lead exhaust remains an issue in older urban areas.

By the time lead came off the market, Midgley’s second great invention, chlorofluorocarbons, were found to be a threat to the atmosphere as well. CFC compounds were so stable they remained in the upper atmosphere for long periods of time. In 1974, scientists Molina and Rowland identified CFCs as damaging to the ozone layer, for which they later won the Nobel Prize. By 1978 the US moved to ban the chemicals from the market, and the rest of world followed suit. Today holes in the ozone layer are healing, but CFCs can take decades to decay, prolonging the damage. Meanwhile political threats to the embargo continue.

Midgley himself came to the rescue. A second class of safer “HFC” hydrofluorocarbons he discovered became replacement refrigerants. But one solution generates new problems—HFCs have now been identified as short-lived but powerful greenhouse gases. In either case, Midgley should be blameless. No one in 1928 could have foreseen the effects of such a discovery.

And that may be the true, unavoidable price of progress as Kettering saw it. Sometimes we have the expertise to predict the effects of our actions. But often there is no way of knowing. Social attitudes towards risk have also evolved since Midgley’s day. Advances in medicine and geoscience enable “better living through chemistry.” But the environmental and worker protections of a few decades back have been met with new pendulum swings favoring industry and globalization. As science accelerates the discovery of new compounds, we live with an ongoing struggle to balance the needs of industry, government and the public.

So today we face the same quandaries that Midgley did. Do we wash our hands of responsibility for the effects of new products and substance, or do we step back and wait for the judgment of experts? Is that even an option when the fastest to market wins?

Internet discussions about Midgley reliably spark extreme attitudes and snap judgments, from full condemnation to total support. The website climateandsecurity.org contends that Midgley has started us on the road to geo-engineering our planet’s future. Perhaps the best legacy of Thomas Midgley, Jr. is the power his story has to make us re-examine the price—and promise—of progress.

Related

Thomas Midgley And The Law Of Unintended Consequences

By Mark Bernstein

Midgley’s Innovation Strategies.

By Mark Martel

Ethyl-leaded Gasoline:

How a Classic Occupational Disease Became an International Public Health Disaster

By William Kovarik, PhD

The Ethyl Controversy: How the news media set the agenda for a public health controversy over leaded gasoline, 1924-1926 William J. (Bill) Kovarik

Biographical Memoir of Thomas Midgley, Jr.

By Charles Kettering

The Secret history of Lead

The Nation, March 2000

Getting the Lead Out

Caltech geochemist Clair Patterson (1922–1995) helped galvanize the environmental movement 50 years ago when he announced that highly toxic lead could be found essentially everywhere on Earth, including in our own bodies—and that very little of it was due to natural causes. By Douglas Smith, Now@Caltech

Clair C. Patterson

Caltech Oral History

By Mark Bernstein

Midgley’s Innovation Strategies.

By Mark Martel

Ethyl-leaded Gasoline:

How a Classic Occupational Disease Became an International Public Health Disaster

By William Kovarik, PhD

The Ethyl Controversy: How the news media set the agenda for a public health controversy over leaded gasoline, 1924-1926 William J. (Bill) Kovarik

Biographical Memoir of Thomas Midgley, Jr.

By Charles Kettering

The Secret history of Lead

The Nation, March 2000

Getting the Lead Out

Caltech geochemist Clair Patterson (1922–1995) helped galvanize the environmental movement 50 years ago when he announced that highly toxic lead could be found essentially everywhere on Earth, including in our own bodies—and that very little of it was due to natural causes. By Douglas Smith, Now@Caltech

Clair C. Patterson

Caltech Oral History

Dayton Innovation Legacy is a multimedia website and educational resource about Engineers Club of Dayton members who represent a living history of innovation for over 100 years. Dayton Innovation Legacy was made possible in part by the Ohio Humanities Council, a State affiliate of the National Endowment for the Humanities. |